Blog

Zuschneidfelle – Your Complete Guide to Cut Fur Materials

In the world of textiles and crafts, fur has always held a special place. From its warmth and softness to its elegance, fur materials have been used for centuries in clothing, accessories, and interior design.

One of the terms you’ll often come across in German marketplaces and craft shops is “zuschneidfelle”, which directly translates to “cut fur pieces.” These are pre-cut sections of natural or artificial fur designed for easy use in DIY projects, fashion, upholstery, and other creative applications.

This guide will help you understand what zuschneidfelle are, their uses, benefits, and how you can choose the best ones for your needs.

What Are Zuschneidfelle?

Definition and Origin

The word “zuschneidfelle” combines two German words:

- “zuschneiden” meaning to cut

- “Felle” meaning furs or skins

Together, it refers to pre-cut fur pieces made from either real animal hides or synthetic fur.

Why They’re Popular

Instead of purchasing a full hide, many people prefer zuschneidfelle because they’re:

- Affordable

- Easier to handle

- Available in manageable sizes for crafting and sewing

Types of Zuschneidfelle

Natural Fur Pieces

These are made from real animal skins, often sourced as by-products of the leather industry. Common types include:

- Sheepskin

- Goatskin

- Cowhide

- Rabbit fur

Each type has its own texture, durability, and warmth.

Artificial (Faux) Fur Pieces

Made from synthetic fibers, faux zuschneidfelle offer:

- A cruelty-free option

- Wide variety of colors and patterns

- Easy maintenance

Common Uses of Zuschneidfelle

1. Fashion and Accessories

Designers often use zuschneidfelle for:

- Coats and jackets

- Fur collars and trims

- Gloves and hats

- Handbags and clutches

2. Interior Decoration

Cut fur pieces are also popular in home design, such as:

- Cushion covers

- Throws and blankets

- Chair upholstery

- Rugs and mats

3. Crafting and DIY Projects

Hobbyists love zuschneidfelle for creative projects like:

- Doll clothing

- Costumes

- Pet accessories

- Art installations

Benefits of Using Zuschneidfelle

Convenience

Pre-cut sizes save time, making them easier to work with than whole hides.

Cost-Effectiveness

Buying smaller pieces reduces costs compared to purchasing a full skin.

Versatility

They can be used for both professional design and small DIY projects.

Eco-Friendly Options

Many zuschneidfelle are by-products, ensuring sustainable use of resources.

How to Choose the Right Zuschneidfelle

Check the Material

Decide whether you want natural fur for authenticity or faux fur for ethical and practical reasons.

Consider the Size

Measure your project needs and choose a piece that matches.

Look at Color and Texture

Select a fur type that complements your design vision—smooth, fluffy, patterned, or plain.

Quality Matters

Ensure the fur is well-processed, durable, and free from defects.

Caring for Zuschneidfelle

Cleaning Tips

- Shake and brush regularly to remove dust.

- For natural fur, avoid soaking in water.

- For faux fur, gentle machine washing may be possible (check labels).

Storage Advice

- Store in a cool, dry place.

- Avoid direct sunlight to prevent fading.

- Use breathable fabric bags instead of plastic.

Where to Buy Zuschneidfelle

Online Stores

Many craft and fabric retailers sell zuschneidfelle online with different sizes, textures, and colors.

Local Craft Shops

You can often find small batches of fur pieces in fabric stores or leather supply shops.

Specialized Fur Dealers

For high-quality natural fur, specialized suppliers may be the best option.

Sustainability and Ethics

Natural Fur Debate

While natural zuschneidfelle are durable and authentic, there are ethical concerns around animal use.

Faux Fur Advantage

Faux options provide cruelty-free alternatives, though they raise questions about synthetic waste.

Eco-Friendly Practices

Some manufacturers now focus on recycled fur or upcycled leather industry by-products, balancing quality with responsibility.

Tips for DIY Projects with Zuschneidfelle

Use the Right Tools

Sharp scissors, rotary cutters, and strong needles are essential.

Plan Your Design

Sketch and measure before cutting to avoid wasting material.

Combine with Other Fabrics

Mixing fur with leather, denim, or cotton creates stylish contrasts.

Start Small

If you’re new to working with fur, begin with a simple project like a pillow cover or keychain.

Customer Experiences with Zuschneidfelle

Positive Reviews

- Affordable for small projects

- Easy to handle compared to full hides

- Great variety of textures and colors

Common Challenges

- Natural fur requires extra care

- Faux fur can shed if poorly made

Frequently Asked Questions (FAQ)

What does zuschneidfelle mean?

It means “cut fur pieces” in German.

Is zuschneidfelle real fur?

It can be either natural or synthetic, depending on the source.

Can beginners work with zuschneidfelle?

Yes, they’re easier to handle than full hides, making them beginner-friendly.

Are they expensive?

Prices vary, but small pieces are generally affordable compared to full animal skins.

Final Thoughts on Zuschneidfelle

Whether you’re a fashion designer, home decorator, or hobby crafter, zuschneidfelle offer a practical and versatile way to work with fur. They save time, money, and effort while opening up endless creative possibilities.

From authentic natural hides to eco-friendly faux options, there’s a zuschneidfelle piece for every project. By learning how to choose, care for, and use them effectively, you can elevate your designs while staying mindful of sustainability.

Blog

Best Practices For Long-Lasting Asphalt Pavements: What Property Owners Should Know

Why Asphalt Durability Matters For Property Owners

The durability of your asphalt pavement impacts everything from curb appeal to long-term maintenance costs. Whether you manage a commercial parking lot, residential driveway, or community pathway, investing in resilient pavement means fewer disruptions and lower repair costs. This is why many property owners trust experts in asphalt paving La Porte IN to guide them through best practices for installation and upkeep.

Asphalt continues to be a top choice due to its reliable performance and cost-effectiveness. However, even premium-quality asphalt requires proper care to maximize its life span. Research indicates that property owners who take a proactive approach to asphalt maintenance avoid premature replacements and benefit from reduced environmental impact, as maintenance reduces resource consumption and waste generation. For those located in regions with fluctuating weather, such as La Porte, IN, these considerations become even more critical.

Common Causes Of Asphalt Deterioration

Over time, even the best-constructed asphalt surfaces will face wear and tear. Common causes include frequent freeze-thaw cycles, exposure to UV radiation, heavy vehicle traffic, and contaminants like oil or gasoline. Additionally, standing water and debris buildup hasten deterioration, leading to visible issues like cracks, potholes, and fading. These issues can escalate quickly if not addressed, risking aesthetics and safety for those who use the pavement.

Regular and timely interventions, as advised by industry professionals and resources such as the American Society of Civil Engineers, can significantly extend pavement life and delay costly repairs. Adopting modern, climate-resistant asphalt mixes tailored to local conditions helps reduce the risk of structural failures and surface issues, ensuring that your investment remains protected year after year.

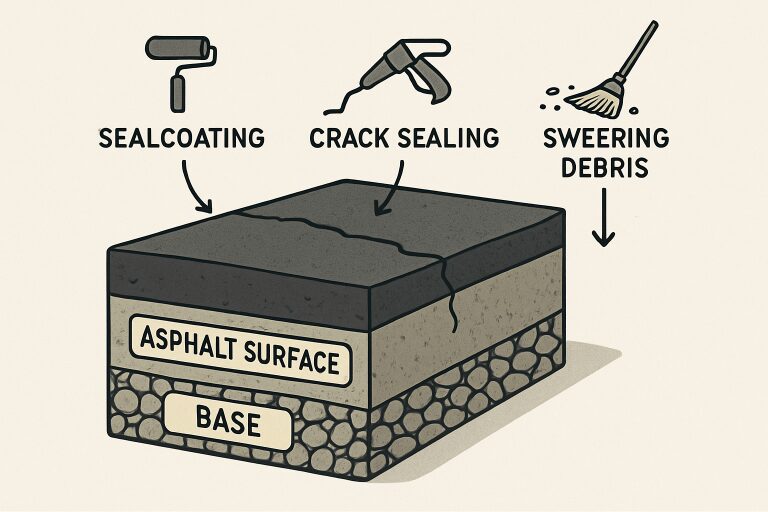

Routine Maintenance Strategies That Work

- Sealcoating: This surface treatment acts as a protective barrier, shielding the asphalt from sun, water, and chemicals. Applied every 2–4 years, sealcoating slows the natural aging process and keeps the pavement looking fresh.

- Crack Sealing: Properly addressing cracks prevents water intrusion, which can undermine the sub-base and trigger potholes. Specialized sealants or fillers ensure a watertight seal for cracks of varying sizes.

- Sweeping and Debris Removal:Regularly cleaning the pavementprevents damage caused by trapped moisture and invasive weeds, which accelerate the asphalt binder’s breakdown.

- Regular Inspections: Professional or routine walk-throughs twice a year can reveal early signs of trouble, allowing for minor, affordable fixes before they develop into significant issues.

Design Factors That Influence Asphalt Longevity

Superior asphalt pavement starts with an innovative design. Integral to this is effective drainage—graded surfaces and strategically placed channels or drains ensure water flows away, minimizing the risk of cracks and potholes caused by pooling. The strength and durability of the foundation matter too. Stabilizing and compacting the soils underneath creates a solid base, preventing future settling or deformation.

Material selection is equally important. Especially in climates with dramatic temperature shifts, contractors recommend asphalt mixes with specialized binders or polymers that resist cracking. According to Asphalt Magazine, advances in materials science are enabling longer-lasting pavements that maintain flexibility and integrity, even after years of exposure to harsh weather and high traffic loads.

Addressing Potholes And Surface Damage Quickly

Unattended potholes quickly worsen and pose hazards to both vehicles and pedestrians. Temporary repairs using cold patch materials can prevent accidents in the short term, but a comprehensive fix requires the removal and replacement of compromised pavement with hot mix asphalt. For heavily trafficked commercial properties, resurfacing large worn sections may offer better long-term value than repeated patching. Quick response is crucial to prevent minor flaws from turning into significant liabilities.

The Environmental Side Of Asphalt Maintenance

Sustainability in pavement management is not only environmentally responsible but can also save costs. Many contractors recycle old asphalt, reducing landfill use and raw material expenses. Using eco-friendly sealants and low-VOC surface treatments aligns pavement care with local environmental regulations while minimizing harmful emissions. For property owners looking to make a positive ecological impact, requesting recycled content and green products from contractors is an easy first step. Learn more from the U.S. Environmental Protection Agency (EPA).

Professional Services Vs. DIY Solutions

While property staff can handle some maintenance tasks, like sweeping or inspecting, larger tasks often require professional experience. Deep structural cracks, major water drainage concerns, or full surface replacements benefit from expert attention to guarantee proper materials, techniques, and compliance with local building codes. Partnering with experienced teams ensures superior workmanship and enlists their insights for ongoing pavement care strategies.

Long-Term Savings From Preventive Care

Reactive repairs quickly add up in both cost and disruption. Studies affirm that implementing a preventive maintenance plan can cut asphalt lifecycle expenses by up to 30%, mainly by avoiding major repairs and extending pavement usability. Beyond financial benefits, regularly maintained asphalt boosts property value, strengthens first impressions for tenants or customers, and enhances overall safety.

Blog

Your Go-To Air Fryer Cookbook: Recipes for Every Craving

Air fryers have become one of the most popular kitchen gadgets in recent years, and for good reason. They make it easy to enjoy your favorite fried foods without the extra oil, mess, and calories. Whether you’re looking for healthy snacks, quick breakfasts, or family-friendly dinners, an air fryer can do it all. In this roundup, we’ve gathered some of the best high-quality air fryer recipes that you’ll want to make again and again.

From crispy vegetables to perfectly cooked proteins, these dishes prove that air fryers aren’t just a trend—they’re here to stay.

Why Choose the Air Fryer?

Unlike deep frying, which submerges food in hot oil, an air fryer uses rapid air circulation to crisp up food with little to no oil. This makes it a healthier option while still giving you that satisfying crunch and flavor.

Air fryers are also versatile, allowing you to bake, roast, and even dehydrate foods. Busy home cooks love them because meals can be prepared faster, and cleanup is minimal. If you’re on a specific diet, the air fryer can help you whip up meals that are both convenient and delicious.

Breakfasts to Start the Day Right

1. Air Fryer Breakfast Potatoes

Who doesn’t love crispy, golden breakfast potatoes? With an air fryer, you can achieve that perfect balance of crunch and softness without excess oil. Toss diced potatoes with olive oil, paprika, garlic powder, and onion powder, then air fry until golden brown. Pair with eggs or avocado toast for a hearty start to your day.

2. Fluffy Air Fryer Pancakes

Yes, you can even make pancakes in an air fryer! By pouring pancake batter into silicone molds or ramekins, you get fluffy, cake-like pancakes that are fun to serve. Top with fresh fruit, syrup, or nut butter for a wholesome breakfast.

3. Air Fryer Eggs

If you’ve never tried making air fryer eggs, you’re missing out on a quick, protein-packed breakfast. You can cook hard-boiled eggs in the shell, bake mini frittatas in ramekins, or make scrambled eggs in minutes. It’s a versatile method that takes the guesswork out of stovetop cooking.

Snack Attack: Crispy and Healthy Treats

4. Air Fryer Kale Chips

Looking for a healthy snack? Kale chips are light, crunchy, and loaded with nutrients. Simply season kale leaves with olive oil and a sprinkle of sea salt, then air fry until crispy. They’re a guilt-free substitute for potato chips.

5. Buffalo Cauliflower Bites

Perfect for game day or movie night, these cauliflower bites pack bold flavor without the calories of fried wings. Toss florets in buffalo sauce, coat lightly with almond flour, and air fry until crispy. Serve with ranch or blue cheese dip for the ultimate snack.

6. Air Fryer Mozzarella Sticks

Indulge in gooey, cheesy goodness with homemade mozzarella sticks. Freeze breaded cheese sticks before popping them in the air fryer. The result? A crispy outer layer with a melted center—perfect for dipping into marinara sauce.

Lunchtime Favorites

7. Crispy Chicken Tenders

Chicken tenders are a family classic, and the air fryer makes them even better. Coat strips of chicken in seasoned breadcrumbs or panko, then air fry until golden brown. These are great for kids’ lunches or quick weeknight meals.

8. Air Fryer Fish Tacos

For a lighter twist, try air fryer fish tacos. Use a white fish like cod or tilapia, season with chili powder and lime, and air fry until flaky. Serve with shredded cabbage, avocado, and a drizzle of crema on corn tortillas.

9. Stuffed Bell Peppers

Air fryers are excellent for cooking stuffed vegetables. Bell peppers stuffed with quinoa, beans, veggies, and cheese cook evenly and develop a slightly charred flavor that enhances every bite.

Dinner Made Easy

10. Juicy Air Fryer Salmon

If you’re looking for a healthy and quick dinner option, salmon is a top choice. The air fryer locks in moisture while crisping up the outside. Season with lemon, garlic, and dill, and serve with roasted veggies or rice.

11. Air Fryer Meatballs

These meatballs are tender, flavorful, and easy to prepare. Combine ground beef or turkey with breadcrumbs, Parmesan, and Italian herbs, then air fry until golden. They’re perfect for spaghetti night or served as appetizers with dipping sauce.

12. Crispy Tofu Stir-Fry

For a vegetarian-friendly dinner, crispy tofu works beautifully in the air fryer. Toss cubes of tofu with soy sauce, sesame oil, and cornstarch, then air fry until golden. Add them to a stir-fry with your favorite vegetables and sauce.

Sweet Treats to End the Day

13. Air Fryer Donuts

Skip the deep fryer and make light, fluffy donuts in your air fryer. Use biscuit dough or homemade dough, cook until golden, and then roll in cinnamon sugar. They’re a fun dessert that feels indulgent but is lighter than the traditional version.

14. Baked Apples

Core apples and stuff them with oats, cinnamon, nuts, and honey, then air fry until tender. This dessert is both wholesome and comforting, perfect for cool evenings.

15. Chocolate Lava Cakes

Yes, you can even make decadent lava cakes in your air fryer. With just a few ingredients, you’ll get a gooey chocolate center surrounded by a fluffy cake exterior—ideal for date night or when you’re craving something sweet.

Final Thoughts

Air fryers have transformed the way we cook at home, making it easier than ever to enjoy crispy, delicious meals with fewer calories and less effort. From quick breakfasts to indulgent desserts, the possibilities are endless. Whether you’re looking for healthy snacks, or creative family dinners, this recipe roundup has something for everyone.

If you haven’t yet explored the full potential of your air fryer, now is the perfect time to start experimenting. These recipes are just the beginning—once you get comfortable, you’ll find yourself air frying almost everything.

So dust off your air fryer, gather your ingredients, and get ready to create meals that are not only quick and healthy but also bursting with flavor. Your taste buds (and your waistline) will thank you.

Blog

Pressure Calibration: Maintaining Accuracy in Critical Systems

Pressure measurement plays a vital role across numerous industries—from ensuring patient safety in medical devices to maintaining process efficiency in manufacturing and preventing catastrophic failures in oil and gas operations. Yet pressure instruments are susceptible to drift, damage, and deterioration that can compromise measurement accuracy. Proper pressure calibration serves as the essential safeguard ensuring these critical measurements remain reliable, accurate, and traceable to recognized standards.

The Fundamentals of Pressure Measurement

Pressure, defined as force per unit area, manifests in several distinct forms that are important to understand for proper calibration:

Absolute pressure measures pressure relative to perfect vacuum (zero pressure), critical in applications like altimeters and vacuum processes. Gauge pressure measures pressure relative to ambient atmospheric pressure and is the most common measurement in industrial applications. Differential pressure measures the difference between two pressure points, essential for flow measurement, filter monitoring, and level measurement in pressurized vessels.

The units of pressure measurement vary across industries and regions, with common units including pounds per square inch (psi), bar, pascal (Pa), inches of water column (inH₂O), millimeters of mercury (mmHg), and many others. Conversion between these units becomes an important consideration in calibration documentation and procedures.

The wide range of pressure magnitudes presents unique calibration challenges—from ultra-high vacuum (10⁻⁹ Torr) in semiconductor manufacturing to extreme high pressures (30,000+ psi) in hydraulic systems and high-pressure processes. Each range requires specialized calibration equipment and methodologies.

Pressure Measuring Instruments and Their Calibration Requirements

Various pressure sensing technologies are employed across different applications, each with unique calibration considerations:

Mechanical Pressure Gauges

Bourdon tube gauges, the most common mechanical pressure instruments, use a curved tube that straightens under pressure, moving a pointer via a mechanical linkage. Despite their simplicity, they require regular calibration due to mechanical wear, vibration effects, and environmental exposure.

Calibration typically involves comparing readings at multiple pressure points across the gauge’s range to a reference standard. Adjustment may involve repositioning the pointer, adjusting the linkage, or replacing worn components. Hysteresis testing (both increasing and decreasing pressures) is important for mechanical gauges due to their mechanical nature.

Diaphragm and capsule gauges, which use the deflection of a flexible membrane to indicate pressure, find application in low-pressure measurements. Their calibration addresses similar mechanical concerns while accounting for their typically lower pressure ranges and higher sensitivity to positioning.

Electronic Pressure Transmitters

These devices convert pressure into standardized electrical signals (typically 4-20mA, 1-5V, or digital protocols) for integration with control and monitoring systems. Modern pressure transmitters may incorporate sophisticated compensation for temperature effects and non-linearity.

Calibration involves applying precisely known pressures and measuring the corresponding output signal. Many modern transmitters allow electronic adjustment of zero and span values without mechanical intervention. Multi-point calibration across the operating range is essential for transmitters used in critical applications.

Smart transmitters with digital communication protocols (HART, Foundation Fieldbus, Profibus) require specialized calibration equipment capable of interpreting and adjusting digital parameters. These transmitters may store calibration data internally and support remote calibration capabilities.

Pressure Transducers and Sensors

These devices convert pressure directly into electrical signals using various sensing technologies including strain gauge, capacitive, piezoelectric, and resonant wire designs. Each technology has unique calibration considerations.

Calibration procedures must account for both pressure response and electrical characteristics. Excitation voltage, circuit impedance, and signal conditioning all affect measurement accuracy and must be considered during calibration.

In many OEM applications, these sensors are calibrated during manufacturing and designed for replacement rather than recalibration when they drift out of specification. However, in critical applications, periodic verification or calibration remains essential.

Pressure Calibrators and Reference Instruments

These specialized instruments serve as working standards for field calibration of other pressure devices. Their own calibration must be particularly rigorous, with direct traceability to national standards and typically lower measurement uncertainty than the devices they calibrate.

Calibration of these instruments often requires primary standards such as deadweight testers or highly accurate reference transducers with current calibration certificates. The calibration typically covers multiple points throughout the range with particular attention to linearity, hysteresis, and repeatability.

Digital pressure calibrators require verification of both their pressure measurement capabilities and their electrical measurement circuits if they calibrate transmitters or transducers.

Pressure Calibration Methods and Equipment

Several approaches to pressure calibration exist, each appropriate for different accuracy requirements and instrument types:

Primary Standards: Deadweight Testers

Deadweight testers represent the gold standard for pressure calibration, directly generating pressure by applying precisely calibrated masses to a piston-cylinder assembly with a known effective area. The pressure generated is calculated from the mass, local gravity, and piston effective area.

These instruments provide exceptional accuracy (typically 0.008% to 0.025% of reading) and serve as primary standards in many calibration laboratories. They require correction for local gravity, air buoyancy, temperature, and other factors to achieve their full accuracy potential.

Proper operation requires meticulous attention to leveling, rotation of weights (to minimize friction), temperature stabilization, and cleanliness of the piston-cylinder assembly. Different fluid media (typically oil, water, or gas) are used depending on the pressure range and application.

Comparison Calibration

This method compares the device under test to a reference instrument of known accuracy while both are subjected to the same pressure. This is the most common industrial calibration approach due to its flexibility and efficiency.

Pressure comparators using hand pumps, screw presses, or regulated pressure sources generate the test pressure applied to both the reference standard and the device being calibrated. Digital pressure calibrators often combine the pressure generation, reference measurement, and documentation functions in a single portable instrument.

For highest accuracy, the reference instrument should have an accuracy at least four times better than the device being calibrated (a 4:1 ratio), though 3:1 or even 2:1 ratios may be acceptable in less critical applications.

Specialized Calibration Methods

Vacuum calibration requires specialized techniques and equipment, particularly for high and ultra-high vacuum ranges common in semiconductor, research, and aerospace applications. Reference instruments include spinning rotor gauges, capacitance diaphragm gauges, and other technologies specific to vacuum measurement.

Differential pressure calibration may use specialized differential pressure calibrators or creative setups with absolute or gauge pressure references. Proper equalization of reference pressures and management of common mode pressures present particular challenges.

Very high pressure calibration (above 10,000 psi) requires specialized equipment with appropriate safety measures due to the stored energy and potential hazards involved. Hydraulic comparison calibrators with pressure multiplication systems are typically employed.

Pressure Calibration Procedures and Best Practices

Effective pressure calibration follows systematic procedures designed to ensure accuracy and reliability:

Pre-Calibration Assessment

Before calibration begins, technicians should examine instruments for physical damage, corrosion, or contamination of pressure ports. For mechanical gauges, the movement should be checked for smoothness and freedom from binding. Zero verification (with no pressure applied) provides an initial assessment of instrument condition.

Environmental conditions including temperature and, for some applications, humidity and barometric pressure should be measured and recorded. These factors can significantly influence measurement accuracy and may require compensation in the calibration calculations.

Pressure Generation and Control

Stable pressure generation is essential for accurate calibration. Systems must be leak-free, with appropriate pressure media for the application (gas for lower pressures and most gauge calibrations, liquids for higher pressures). Proper bleeding of air from hydraulic systems is critical to prevent measurement errors due to compressed air pockets.

Adequate stabilization time must be allowed after each pressure change before readings are recorded. This stabilization period accounts for adiabatic heating/cooling effects, mechanical settling, and fluid dynamics within the calibration system.

Data Collection and Analysis

Multiple readings should be taken at each calibration point to verify stability and repeatability. Calibration typically proceeds from zero to maximum pressure in defined increments, often following a standardized sequence such as 0%, 25%, 50%, 75%, 100%, 75%, 50%, 25%, 0% of full scale to detect hysteresis effects.

The collected data must be analyzed to determine the instrument’s accuracy, linearity, hysteresis, and repeatability. These performance characteristics are compared against the manufacturer’s specifications or application requirements to determine pass/fail status.

Adjustment and Post-Calibration Verification

When instruments are found out of tolerance, adjustment may be performed according to manufacturer procedures. This might involve mechanical adjustments for analog gauges or electronic zero and span adjustments for transmitters and transducers.

Following any adjustment, a complete post-adjustment calibration must be performed to verify that the instrument now meets specifications across its entire range. Both as-found (before adjustment) and as-left (after adjustment) data should be documented in the calibration record.

Documentation and Reporting

Comprehensive calibration records should include the device identification, reference standards used (with their calibration traceability), environmental conditions, pre and post-adjustment readings, measurement uncertainty, and technician information.

The calibration certificate provides evidence of traceability and documents the instrument’s performance. For regulated industries like pharmaceuticals or aerospace, these certificates are essential components of quality management and compliance documentation.

Special Considerations for Various Industries

Pressure calibration requirements vary significantly across different sectors:

Oil and Gas

In oil and gas production, processing, and transportation, pressure instruments play critical safety and operational roles. Wellhead pressure monitoring, pipeline pressures, and process vessel pressures all require regular calibration to ensure both safety and product quality.

Explosion hazards in many oil and gas environments require intrinsically safe calibration equipment. Offshore platforms present additional challenges with limited access and harsh marine environments, often necessitating on-site calibration capabilities.

High pressures (often exceeding 20,000 psi in some applications) and hydrogen sulfide exposure in sour gas applications create special challenges for both instruments and calibration equipment. Calibration programs must address these extreme conditions while ensuring personnel safety.

Pharmaceutical and Biotechnology

In pharmaceutical manufacturing, pressure calibration supports critical processes including filtration, fermentation, freeze drying (lyophilization), and sterile filling. FDA regulations and cGMP requirements mandate well-documented calibration programs with clear traceability.

Hygienic pressure sensors with sanitary connections require special handling during calibration to maintain cleanliness and prevent contamination. Calibration procedures must address the unique characteristics of these instruments, including their membrane-type pressure sensors.

Steam sterilization processes (autoclaves) rely on precise pressure-temperature relationships to ensure sterilization efficacy. Calibration of these systems requires coordinated temperature and pressure calibration to maintain validated sterilization cycles.

Aerospace and Defense

Aircraft systems rely on precisely calibrated pressure instruments for altimeters, airspeed indicators, engine pressure ratio gauges, and hydraulic systems. Calibration must meet stringent requirements specified in standards such as AS9100 and various military specifications.

Environmental testing chambers that simulate high-altitude conditions require pressure calibration to accurately reproduce atmospheric conditions at different elevations. These calibrations directly impact the validity of equipment qualification testing for aerospace applications.

Missile and rocket systems utilize pressure measurements in propulsion systems, where accuracy directly impacts performance and safety. These specialized applications often require custom calibration approaches with exceptionally low measurement uncertainty.

Healthcare and Medical Devices

Blood pressure monitoring equipment, from manual sphygmomanometers to automated vital signs monitors, requires regular calibration to ensure accurate patient diagnosis and treatment. Calibration procedures must follow specific standards for these devices, including AAMI/ANSI SP10.

Ventilators and anesthesia machines rely on accurate pressure measurements to deliver appropriate respiratory support. Calibration of these life-critical devices must be performed with exceptional care and documentation.

Negative pressure rooms for infection isolation depend on precise differential pressure control and monitoring. Calibration of these systems directly impacts infection control effectiveness in healthcare facilities.

Calibration Management and Frequency Determination

Effective pressure calibration programs require systematic management:

Risk-Based Calibration Intervals

Modern calibration management approaches have moved from rigid time-based schedules to risk-based interval determination. This approach considers factors such as the criticality of the measurement to process control, safety, or product quality; historical calibration data revealing drift patterns; environmental conditions including vibration, temperature fluctuations, or corrosive atmospheres; and manufacturer recommendations.

Statistical analysis of calibration history, including control charts and drift analysis, supports scientific determination of optimal intervals that balance reliability and cost. Some regulated industries still mandate maximum intervals regardless of historical performance, but even in these cases, risk assessment can identify instruments requiring more frequent attention.

Calibration Management Software

Modern organizations increasingly rely on specialized software to manage comprehensive calibration programs. These systems provide automated scheduling, documentation storage, trend analysis, and compliance reporting specifically designed for pressure instrument management.

Advanced systems incorporate measurement uncertainty calculations, guard banding to account for calibration uncertainties, and statistical process control techniques to optimize calibration intervals. Mobile applications enable technicians to access procedures and record results in the field, improving efficiency and data integrity.

In-Situ Calibration vs. Laboratory Calibration

Organizations must decide whether to remove instruments for laboratory calibration or perform calibration in place. In-situ calibration minimizes process disruption and evaluates instruments under actual operating conditions, but may face limitations in accuracy due to environmental factors and available reference standards.

Laboratory calibration provides controlled conditions and access to more accurate reference standards, but requires instrument removal and reinstallation with associated process disruption and potential for installation errors. Many organizations employ a hybrid approach, with routine verifications performed in-situ and full calibrations conducted in a laboratory environment.

Recent Advances in Pressure Calibration

The field continues to evolve with technological improvements:

Digital Calibration Technology

Modern digital pressure calibrators integrate multiple functions—pressure generation, measurement, documentation, and communication—in portable, user-friendly packages. These devices can automatically document calibration procedures, calculate errors, and generate calibration certificates in the field.

Wireless technology allows calibration data to be transferred directly to calibration management software without manual transcription, reducing errors and improving efficiency. Some systems support remote expert assistance during complex calibrations through real-time data sharing.

Automated Calibration Systems

Automated pressure calibrators can cycle through entire calibration sequences with minimal operator intervention, improving consistency and reducing labor costs. These systems are particularly valuable for multi-point calibrations of complex instruments like smart transmitters.

Some advanced systems incorporate barcode or RFID scanning to automatically identify instruments and load appropriate calibration procedures, further reducing potential errors in the calibration process.

Improved Reference Standards

Reference transducer technology continues to improve, with modern pressure transducers achieving accuracies approaching traditional deadweight testers but with greater convenience and applicability to field calibration. Quartz reference transducers can achieve uncertainties below 0.01% of reading over wide pressure ranges.

Resonant silicon pressure sensors offer exceptional stability and reduced sensitivity to environmental factors, making them excellent reference standards for field calibration applications. These technological advances are making high-accuracy pressure calibration more accessible for routine industrial applications.

Looking to the Future of Pressure Calibration

As industrial processes become increasingly automated and quality requirements more stringent, pressure calibration will continue to evolve:

Digital transformation is creating fully paperless calibration workflows with electronic approvals, automated uncertainty calculations, and direct integration with quality management systems. Remote calibration capabilities are expanding, allowing experts to supervise or perform calibrations at distant locations using connected calibration equipment.

Predictive analytics increasingly guides calibration scheduling, with AI algorithms analyzing performance patterns to optimize intervals and predict potential failures before they occur. These advances promise to make pressure calibration more efficient and effective while maintaining or improving measurement integrity.

Making the Right Choice for Pressure Calibration

Organizations seeking pressure calibration services should consider several key factors:

Technical capabilities must align with specific application needs, including the provider’s pressure ranges, measurement uncertainty, and types of instruments they can calibrate. Accreditation, particularly ISO 17025, provides assurance of technical competence and measurement traceability. Experience in specific industries ensures understanding of regulatory requirements and application-specific challenges.

Turnaround time directly impacts operational efficiency, with some providers offering expedited service to minimize equipment downtime. For organizations with multiple facilities or large instrument inventories, a calibration provider with broad geographic coverage like SIMCO Electronics can provide consistent calibration approaches across all locations.

The Value Proposition of Professional Pressure Calibration

While calibration requires investment, the return on this investment manifests in multiple ways:

Process safety depends on accurate pressure measurement, particularly in high-pressure systems where overpressure can lead to catastrophic failures. Accurate pressure measurement directly impacts product quality in many manufacturing processes, from pharmaceutical production to food processing and semiconductor manufacturing.

Energy efficiency often depends on optimized pressure control in compressed air systems, steam generation, and fluid handling, where calibrated instruments enable fine-tuning for maximum efficiency. Regulatory compliance across numerous industries requires documented pressure calibration programs with clear traceability.

Maintenance cost reduction comes from early identification of instrument problems through calibration programs before they cause process issues or equipment damage. Ultimately, comprehensive pressure calibration programs protect both personnel safety and organizational assets by ensuring that critical pressure systems operate as designed.

Looking Ahead

Pressure measurement remains fundamental to countless industrial, research, and healthcare applications—from ensuring patient safety in medical devices to optimizing energy efficiency in manufacturing and preventing catastrophic failures in high-pressure systems. As technology advances and regulatory requirements evolve, the importance of proper pressure calibration only increases.

By implementing comprehensive, risk-based pressure calibration programs and partnering with qualified calibration providers, organizations ensure that their pressure measurements remain accurate, reliable, and traceable. This investment in measurement quality provides the foundation for operational excellence, compliance, and safety across virtually every industry where pressure measurement plays a critical role.

Through continued advancement in calibration technology and methodologies, the future promises even greater efficiency and effectiveness in pressure calibration, supporting the increasingly demanding requirements of modern industrial processes and critical applications where precise pressure measurement makes all the difference between success and failure.

-

Tech6 months ago

Tech6 months agoSotwe STW Explained How a Radical Platform is Redefining Online Expression

-

Entertainment8 months ago

Entertainment8 months agoHow Do I Turn On the Beatbot?

-

Motherboard Guide1 year ago

Motherboard Guide1 year agoAre B750 Motherboard A Good Choice – A Complete Overview!

-

Blog1 year ago

Blog1 year agoHow To Find My Motherboard Model And Bios Version – A Detailed Overview!

-

Motherboard Guide1 year ago

Motherboard Guide1 year agoAre Gigabyte Motherboards Good – A Comprehensive Review!

-

Blog3 months ago

Blog3 months agoHer Love Is A Kind Of Charity Password – The Hidden Meaning Behind the Phrase!

-

Motherboard Guide12 months ago

Motherboard Guide12 months agoB75 Motherboard What Generation Cpu Is Supported – B75 Motherboard Cpu Support!

-

Motherboard Guide4 months ago

The Ultimate Croatia Travel Guide for First-Timers: Everything You Need to Know Before You Go